Table of Contents

Granite Slabs: Uses, Sizes, Cost, Pros, Cons, and Everything You Need to Know Before Buying

Granite slabs are an increasingly popular choice for homeowners and designers alike, celebrated for their natural beauty and durability. One of the most significant pros of granite slabs is their ability to withstand heat, scratches, and stains when properly sealed, making them ideal for kitchen countertops where culinary activities abound.

What is Granite Slab?

Granite slabs are large, flat pieces of granite, a natural igneous rock formed from the crystallization of magma beneath the Earth’s surface. These slabs are prized in construction and interior design for their durability, aesthetic appeal, and unique patterns that result from the mineral composition of each stone. Typically polished to a high sheen, granite slabs display vibrant colors ranging from deep black and rich browns to striking blues and greens, often interspersed with flecks of quartz or mica that shimmer under light. Due to its resistance to scratching, heat, and staining when properly sealed, granite is an ideal material for kitchen countertops, bathroom vanities, flooring tiles, and even monumental sculptures.

Where Can We Use Granite Slabs?

Granite slabs are incredibly versatile and can be utilized in a variety of applications, each showcasing their durability and aesthetic appeal.

1. In the kitchen, these magnificent stone surfaces serve as stunning countertops that not only elevate the visual charm but also provide a heat-resistant working area for culinary enthusiasts.

2. Bathrooms benefit equally from granite slabs, where they can be employed as elegant vanities or shower walls, bringing an air of luxury while remaining easy to clean and maintain.

3. Beyond interiors, outdoor spaces also find value in granite; patios adorned with polished granite slabs create striking dining areas or fire pit surrounds that withstand weather elements without losing their luster.

4. Additionally, commercial properties utilize granite slabs for flooring and cladding due to their resilience against heavy foot traffic and environmental wear, making them ideal for high-traffic areas like hotels or shopping centers.

5. Moreover, artistic expressions come alive when fabricators transform granite into intricate sculptures or bespoke furniture pieces; thus extending its usage far beyond traditional settings into realms of creativity and design innovation.

How is Granite Sealed?

When granite slabs are installed, they essentially cover the entire countertop area with their large pieces of stone. If one slab does not fully cover the space, an additional piece can be added to extend it. This will result in a seam where the two pieces meet, that is typically filled with grout.

The skilled craftsmen who install high quality granite have the ability to create seams that are nearly imperceptible. However, there may be instances where the seam is noticeable due to the color and pattern of the granite. For example, if white granite is paired with grey sealant, it may result in an unappealing appearance. Additionally, due to the natural characteristics of stone, edges at joints may not align perfectly. This not only detracts from the overall aesthetic, but could also pose a potential tripping hazard.

In addition to the type of stone, color, and surface finish, it is important to determine the size and quantity of slabs needed. When selecting your slab, keep in mind the number of pieces required and the preferred thickness.

What is the Standard Size of Granite Slab?

An average granite slab sizes are about 8′ * 3′ and above. The thickness of granite is usually 16mm to 18 mm depending upon its length and breath. Each thickness offers a different look.

When it comes to granite slabs, the standard dimensions play a crucial role in both aesthetic appeal and practical application. Typically, these slabs are available in thicknesses ranging from 15 mm to 18 mm, providing a robust yet manageable weight that suits various architectural and design needs.

The common slab size of 8′ x 3′ serves as a versatile foundation for numerous projects—from kitchen countertops to elegant flooring solutions—while larger formats can be sourced for expansive surfaces or statement pieces in commercial settings.

Known for its durability and timeless beauty, each slab showcases unique veining patterns and color variations intrinsic to this natural stone, making every piece one-of-a-kind while adhering to industry standards that ensure structural integrity.

What is the Cost of Granite Slab?

The cost of granite slabs can vary significantly based on several factors, including the origin of the stone, its color and pattern complexity, and the size required for your project. Typically ranging from Rs 60 to Rs 1800 per square foot, granite slabs sourced from high-demand regions like Brazil or India can command a premium price due to their unique aesthetics and durability.

Additionally, rare colors or intricate veining patterns may further inflate costs as they become coveted choices among homeowners and designers alike. Beyond just material expenses, one must also consider fabrication fees which encompass cutting, polishing, and finishing processes that are essential in transforming raw granite into beautiful granite countertops or flooring solutions.

Installation costs add another layer of financial consideration; skilled labor is often necessary to ensure precise fitting and proper support structures are in place for these heavy materials.

How Do You Install a Granite Slab?

The installation of a granite slab demands high levels of accuracy and expertise. It is not suitable for inexperienced individuals or DIY projects. A keen attention to detail, specialized tools, and professional knowledge to install a slab of granite. Additionally, it is important to keep in mind that the more expensive the material, the greater the cost of labor for installation. Any mistake during the process can result in costly material wastage. This applies especially when using granite for vertical cladding due to its heavy weight.

How Granite Slabs are Made?

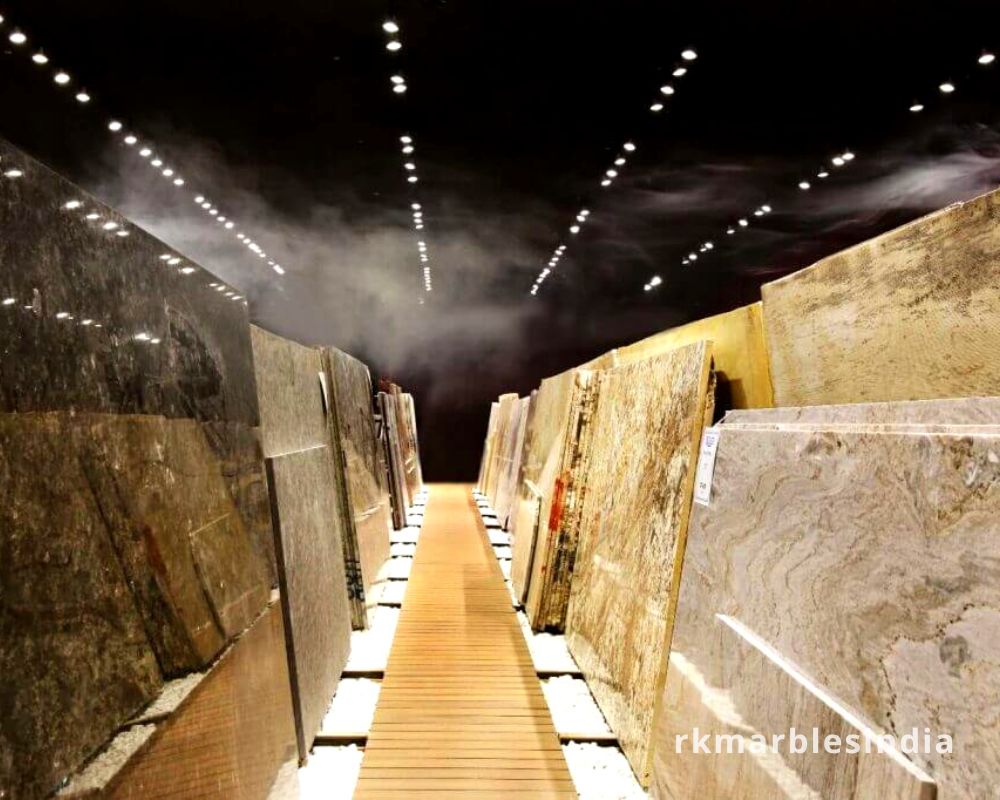

To create a granite stone slab, the initial stage is to extract it from the earth. Mining companies utilize powerful machines to blast and retrieve the raw granite from quarries. The stone is initially rough and must be sent to workshops for further processing. There, specialized milling machines are employed to cut and polish the granite into a smooth slab. The final product typically ranges from 7 to 9 feet in length and can often be found on display in granite showrooms.

Are Granite Slabs Good?

- Granite slabs have gained immense popularity in both residential and commercial spaces, primarily due to their exceptional durability and timeless aesthetic appeal.

- Known for being one of the hardest natural stones available, granite slabs are resistant to scratches and heat, making them an ideal choice for kitchen countertops where culinary activities can put surfaces to the test.

- Beyond their practical benefits, these slabs come in a myriad of colors and patterns—each piece uniquely formed by nature—which allows homeowners and designers alike to create stunning visual displays that can enhance any decor style from rustic charm to modern elegance.

- Moreover, when properly sealed, granite slabs resist staining from common household substances like oils or acidic foods, ensuring they maintain their luster over time with minimal upkeep.

- This combination of resilience and beauty makes granite slabs not just a functional surface but also a long-term investment in the overall value of your property.

Pros of Granite Slab:

When considering granite slabs for countertops or surfaces, it’s essential to weigh the pros and cons carefully. On the plus side, granite is renowned for its durability; it can withstand heat, scratches, and general wear and tear far better than many other materials. Its stunning natural patterns provide a timeless elegance that enhances any space, making each slab unique—a true work of art. Additionally, granite is relatively low-maintenance when sealed properly; spills can be wiped away easily without staining.

Cons of Granite Slab:

However, there are drawbacks to consider as well. The price of granite slabs tends to be on the higher end compared to laminate or even some engineered stones. Installation can also be cumbersome due to their weight; professional help is often necessary which adds to overall costs. Furthermore, while sturdy against most kitchen threats, excessive force could still chip or crack these beautiful surfaces if mishandled. Lastly, sourcing certain colors might involve environmental considerations related to quarrying practices that aren’t always transparent.